So I was a bit nervous about cutting the plywood. It seemed so thin and I was worried about tearout. So I made a zero clearance insert for the 20tpi DeWalt ply blade I got. It’s pretty easy to make. Unfortunately the only way to attach it to the base of my saw is via carpet tape.

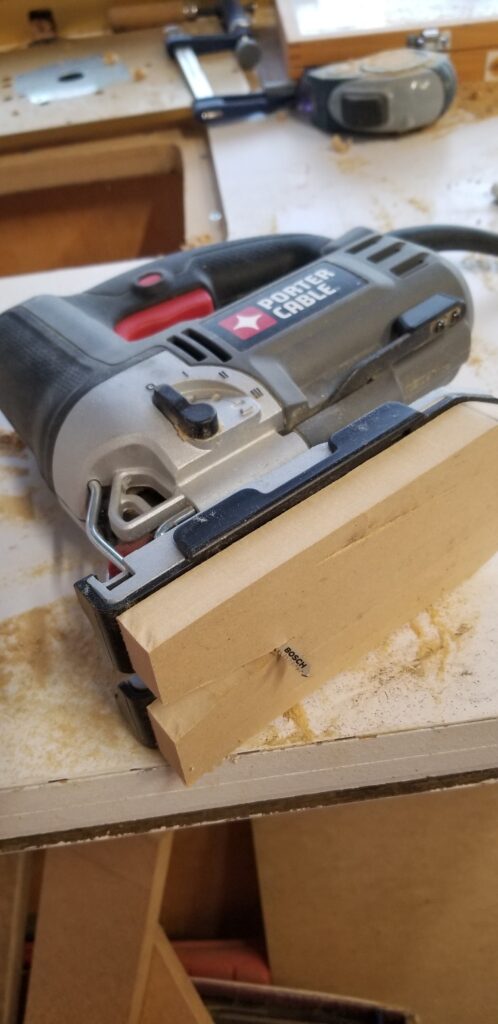

luckily cutting with the Porter Cable jigsaw was easier than I remembered. Make sure you set the saw so the teeth go straight up and down.

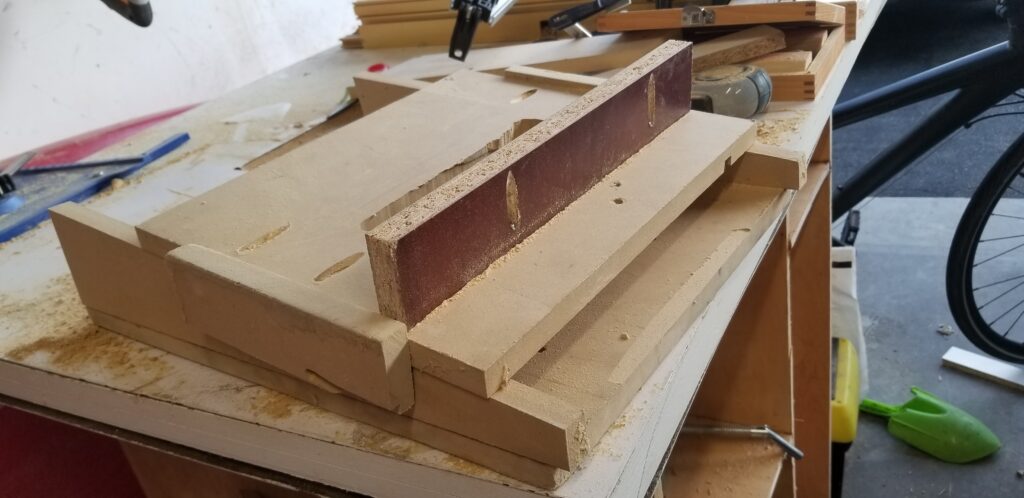

Scarf joint jig

Even though the jemwatercraft plans call for butt or fiberglass taped joints I decided to try and go for scarf joints after reading about all 3 of them. This gives the best strength, weight and visual look. It doesn’t seem that much harder if a jig is used. I created one with this design for my router as people suggested it produced cleaner cuts than circular saws.

Of note, there are side rails holding my router guide in place to the slope rails. I went with this design vs the others where the router is fixed to a base that you slide back and forth because I was afraid my base would become non perpendicular with the slopped rails making the cut off a bit.

With this design the base will always be perpind6 giving the correct angle. My Rigid router slides Cross the top of the base with a guide to help it.

I tested it out on some scrap and it worked pretty well the only problems are the bit has to be extended a bit to reach the workimg surface. Also it can be a bit hard to slide the router back and forth on the mdf. So if your making one maybe melamine for the base and the rails a bit lower.

One nice plus is you can clamp the base to the slopped rails if you wanna take it slow and safe.