First time fiberglassing. There seemed to be two methods. The CLC method of doing sections at a time and Nick Schade’s method of saturating the fiberglass everywhere and coming back to squeeze out the excess. I had estimated this step would take a bit over an hour based in Nick Schade’s video. Well, the Sabalo … Read More “Its Fiberglassing Time!” »

Author: Mike

Started sanding down the outside of the hull. I started with 60 grit by hand. The reason I wanted to start by hand was to get a feel for it, and especially the chines I feel needed some work to get the correct shape and feather in some of the edges. It took forever. After … Read More “Let the sanding begin” »

So this step feels like it’s taking forever. It started with tacking together panels B-D. Than we had to remove the inner frame, restitch supports, stitch Panel A and than tacking that in. Somewhere in that we also restitched the bow with the jig, carefully remove the jig and tack the bow. I’ve since filled … Read More “Epoxy fillets” »

It took longer than I thought it would. Buy finally all the hull panels are stitched up and all but the last one have epoxy fillets holding them along. Note of advice for future builders, leave the stitches a bit loose and popsicle sticks are super useful for helping to keep the shape. Also don’t … Read More “Hull panels all stitched” »

Finally got to stitching the hull together. 18 Ga copper wire does seem to be perfect as everyone says. It held the stern and bow pieces together really well. Those parts were definitely challenging to do. It’s super cool opening up the bottom hull panels and having a curved hull shape come together. Everything seems … Read More “Stitching the hull together” »

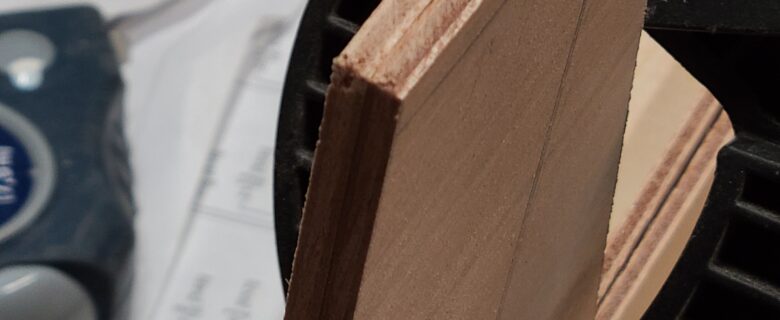

This part of the kayak build has been Maki g me nervous. I debated whether I should just fiberglass butt join them, block butt join them or scarf them. Everything I read suggested scarfing was the way to go. Earlier I posted about the router jig I made to scarf the panels together. Turns out … Read More “Scarfing panels” »

Wait, I’m building a stitch and glue right? Cutting strips? Yeah for the cleats to support the flooring. So off to home Depot. Found some thin wood that was suitable. Used the circular saw to cut them out. I have a jig I’ve always used to cut with the saw. So all the pics I’ve … Read More “Cutting strips for cleats” »

Got most of the internal panels cut out. A few key locations have been moved a bit, so some math had been involved so that panels still fit together. Mainly because this kayak will so some duty as a tandem when our daughter is up front we wanted to expand the cockpit. The aft of … Read More “Quick peak at how internal panels look” »

Having never done this it’s a bit scary. I’ve gone with the strategy of cutting proud and sanding back to the drawn curves. I’m using some 2x4s with OSB on top to support the ply while cutting. some scraps help support the other side while I cut. I’m using 4mm Okoume I got from Noah’s … Read More “Cutting out hull panels” »

So I was a bit nervous about cutting the plywood. It seemed so thin and I was worried about tearout. So I made a zero clearance insert for the 20tpi DeWalt ply blade I got. It’s pretty easy to make. Unfortunately the only way to attach it to the base of my saw is via … Read More “Getting cutting tools ready” »